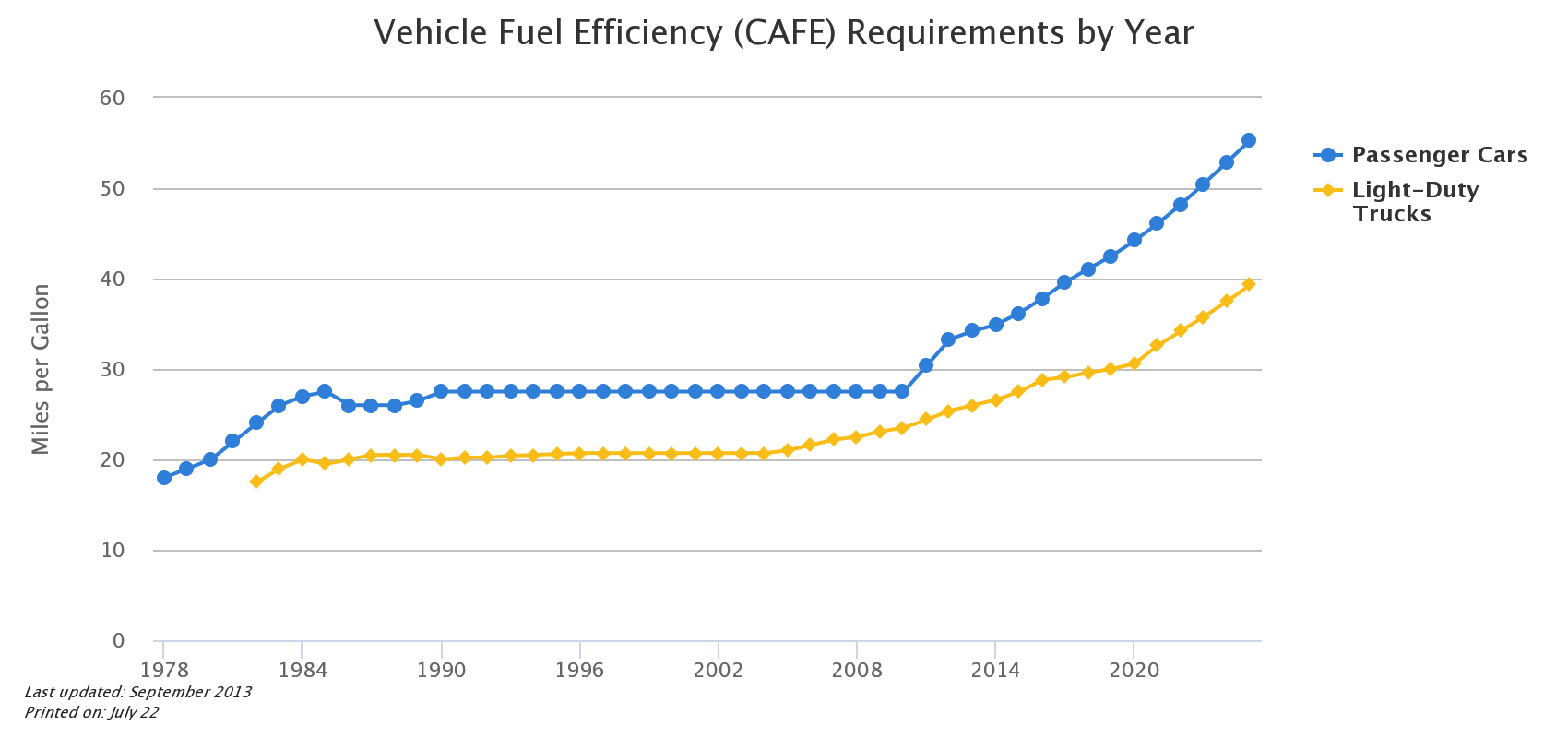

The automobile is at its turning point, yet again. Rising fuel prices, stricter fuel efficiency standards, environmentally conscious customers, and the race for CASE (Connected, Autonomous, Shared Mobility and Electrification) are pushing automakers to evolve rapidly. They are challenged with a huge task to take a strategic direction about the type of powertrain, structural and battery materials and the type of chargers and its infrastructure to deploy.

Figure 1: Vehicle Fuel Efficiency Requirements by Year

As customers watch this rapidly evolving automotive race, they are sometimes confused with what is the right choice to make for a purchase that they may typically stick with for the next 5-10 years at the least. This article reviews the segments of the electrical vehicle (EV) industry as new EV companies are launching their products in the market, while the incumbents are coming up with their own hybrid and battery electric vehicle offerings (BEV). The competition is definitely heating up. Considering the shift toward electrification, customer will be able to better make a decision based on the segment that they can relate to.

The electrical vehicle industry can be segmented into the following types

1) Powertrain

2) Battery Chemistry

3) Vehicle Type

4) End use applications

Powertrain

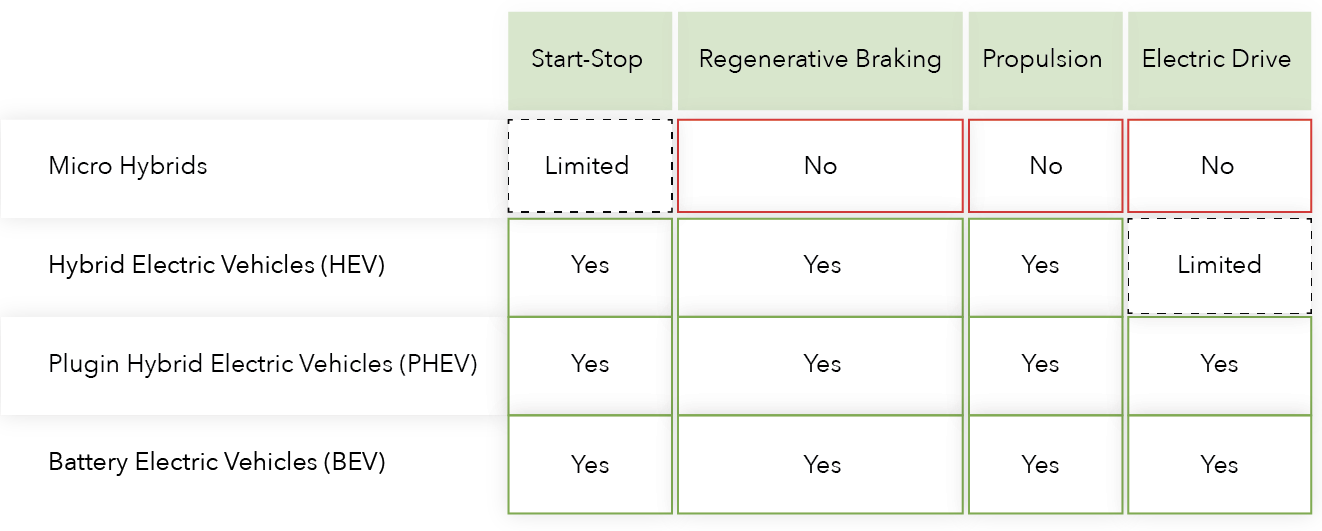

Technically, the electric industry can be segmented using the type of Powertrain. The evolution of powertrain started almost a decade ago with micro hybrids in the market that provided limited features such as start-stop. In start-stop, the engine is shut off during idling while the battery supports the electronic applications such as radio, light, and air conditioning. The battery then restarts the vehicle for it to be able to move from the idling position. The technology then progressed to regenerative braking in which the kinetic energy is harnessed during braking to recharge the battery for start-stop and other functions. Today, most of the electric vehicle market is dominated by HEVs, PHEVs and BEVs that include functions such as propulsion and all electric drive.

Figure 2: Evolution of Vehicle Powertrain

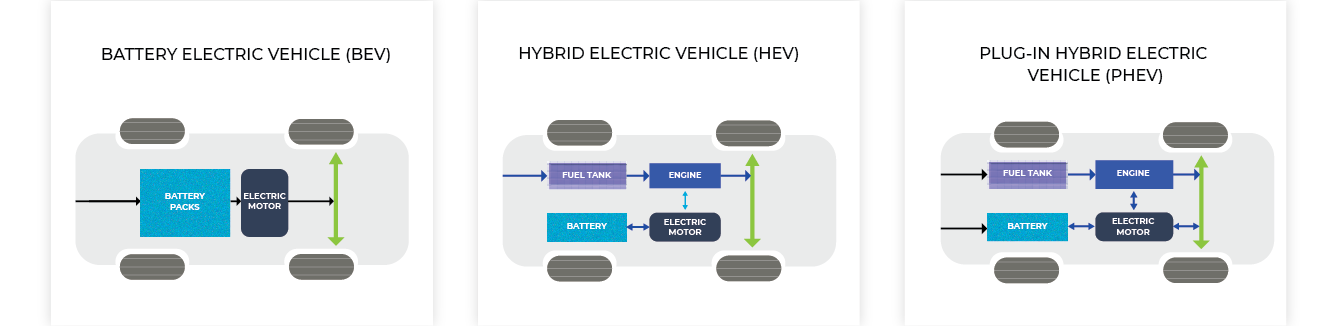

The overall operating principle of HEV, PHEV and BEV is similar in that battery power drives the motors which in turn rotates the wheel. The key difference is how the battery is charged – through grid, regenerative braking or both. Figure below shows the difference of their operation.

Figure 3: Schematic showing operating principle of EVs

Battery Chemistry

The Li-Ion battery has been the leading technology in the consumer electronics industry. It also finds application in the automotive industry for its high power-to-weight ratio which makes the vehicles fast and energy efficient. The Li-ion battery is a rechargeable battery where lithium ions move from the negative electrode to the positive electrode during discharge and back when charging. Each lithium-ion cell contains 4 major parts: Cathode, Anode, Electrolyte, and Separator. Metals such as Cobalt, Manganese and Nickel are also used in different formulations that affect parameters such as life cycles, power density and energy density. These other Lithium-ion batteries such as Lithium Iron Phosphate - LFP, Nickel Cobalt Manganese – NMC, Lithium Cobalt Oxide – LCO have emerged as better alternatives in certain applications. However, Lithium is the only metal that goes into cathode and its supply is very much driven by geopolitical tensions. Automakers are aware about the impact it may have on their EV production and hence are exploring alternative chemistries.

Some of the alternative battery technologies such as metal air, solid-state, lithium-sulfur batteries are currently under research and may emerge as viable options in the near future.

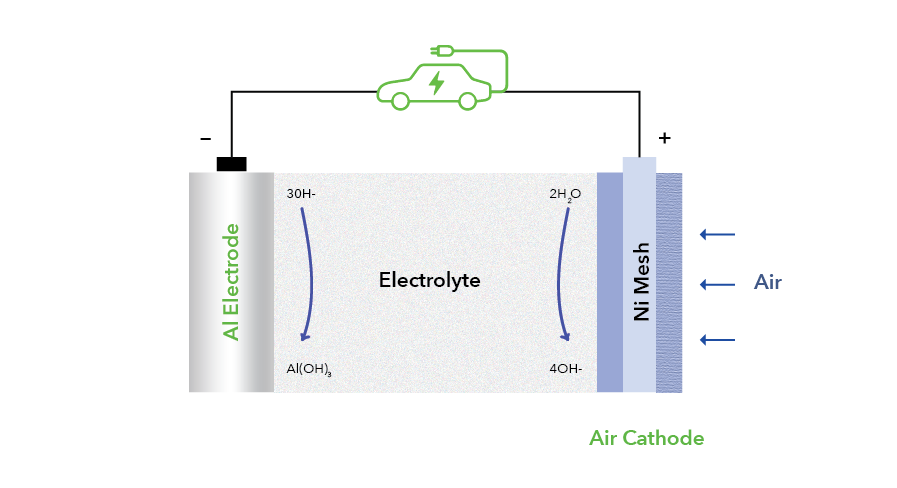

Al Air battery

Metal-air technology enables the generation of electricity from a combination of oxygen from the free air with metals such as aluminium and zinc. Aluminium–air batteries consist of an aluminum anode, an air cathode and an electrolyte which is salty, alkaline, and nonaqueous solutions. Aluminium air batteries have very high energy density of 8,100 Wh/kg. They are environmentally friendly, recyclable, and potentially low cost. Phinergy, an Israel based company is planning to use this technology for EVs. Currently they have set up Pilot project with Indian telecom manufacturer for grid storage. They also formed a joint venture with Indian Oil Corporation Limited (IOCL) for manufacturing batteries for EV applications.

Figure 4: Representation of Al-Air batteries

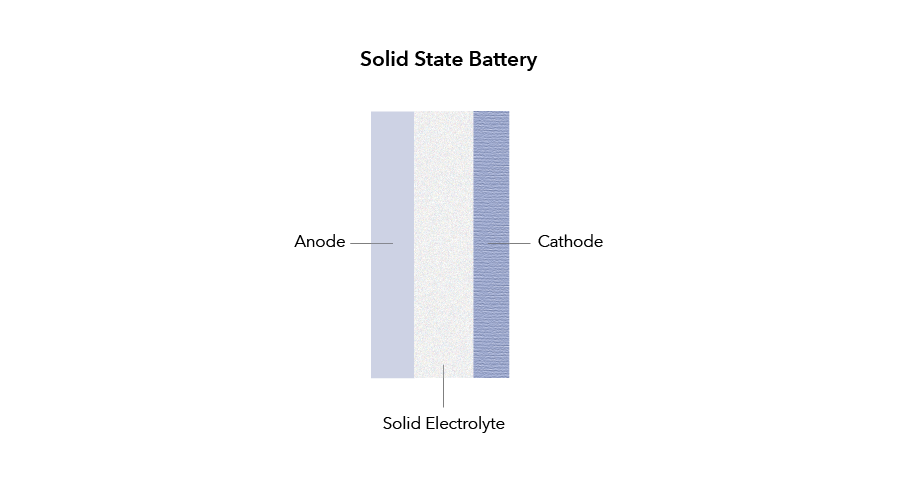

Figure 5: Representation of Solid State Batteries

Solid State batteries

Solid State Batteries (SSB) are ubiquitous in electronic applications such as laptops and mobile phones. However, their application in EV mobility is still in its nascent stage. SSB’s with high cycle-life present strong potential to power future electrical vehicles once manufactured at scale. Solid-State batteries are characterized with improved safety, higher energy density, faster charging times, and longer life. However, Solid State Electrolyte material are too costly and difficult to scale up for high volume manufacturing. As per a report by Future Bridge Consulting, it would take 5 years or more to achieve the cost parity between Li-ion and SSB. Nissan Motors is working towards its roadmap for 2030 for EVs which will include a SSB with 2X energy density as compared to the current Lithium ion batteries.

This article segments the Electric Vehicle market by powertrain and battery chemistry. Continue reading the second part of the article in another link on our website which describes EV segmentation by Vehicle Type and End Use Applications.

Sources:

1) CAFE Standards 2017-2025 : U.S. Environmental Protection Agency CAFE 2017-2025 Final Rule

3) https://www.sciencedirect.com/topics/engineering/aluminum-air-battery

4) https://www.futurebridge.com/blog/solid-state-battery-powered-mobility-by-2025/